Project Description

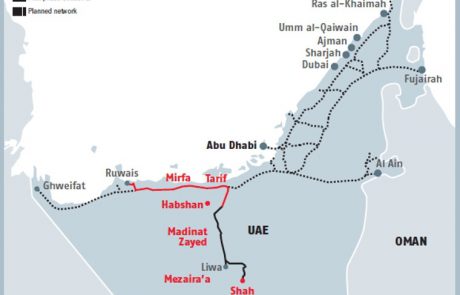

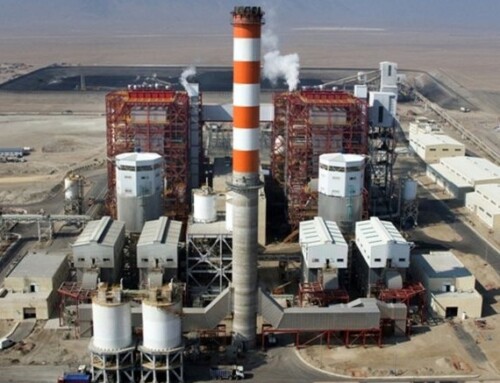

RUWAIS RAILWAY PROJECT – SHAH – HABSHAN

OBJECTIVES

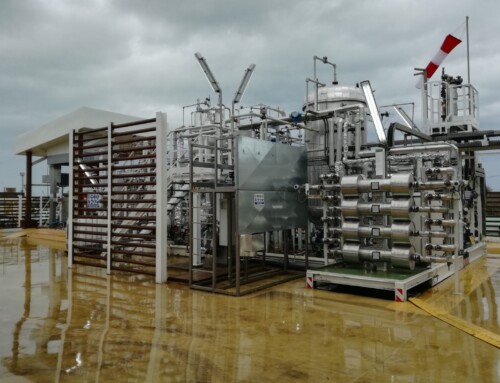

The project involves the construction of a stretch of railway linking Shah – Habshan – Ruwais, by the Joint Venture consisting of Saipem, Tecnimont and Dodsal. The project, in addition to the railway construction, includes the erection of a number of buildings intended for the maintenance and parking of diesel locomotives to be used in the rail-road stretch.

Sector: Oil&Gas

Year: 2013 – 2014

Location: Abu Dhabi, United Arab Emirates

Direct client: Renco Spa

Final client: Ethiad Rail

MAIN ACTIVITIES AND SOLUTIONS

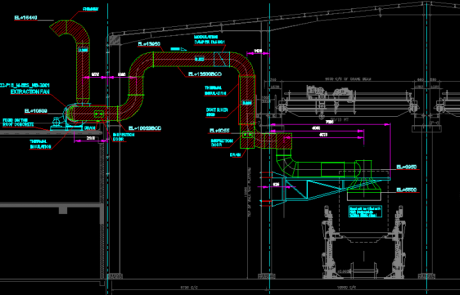

In 3 of these buildings, Trillini Engineering designed an extraction system to remove the exhaust gases generated by the parking diesel locomotives. The system provides three different solutions to house the extractor fans, where the fumes are conveyed at a temperature of around 500° C:

- System with fixed fan;

- System with movable fans and wall-mount arm;

- System with motor driven trolleys and flexible hose for gas extraction.

The collected gases are expelled to the outside by means of specific extractors and conduits. This system allows to preserve a high air quality in the indoor environment, to allow the workers to safely operate during the ordinary maintenance activities which require the locomotive operation.

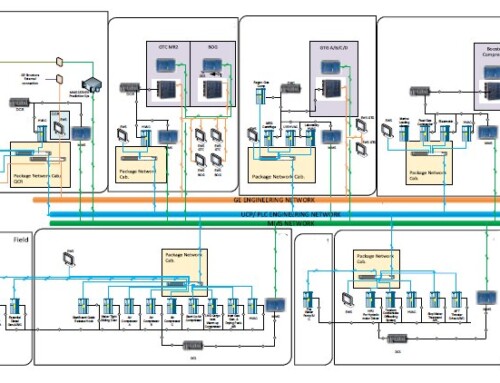

During the project, Trillini Engineering drafted most of the required documents, specifically the documents requiring approval by the client (P & ID, Flow Diagram, Equipment Layout, wiring diagrams, etc..) and the documentation addressing the selection of vendors for the supply of materials and equipment. Finally, the technological uniformity of economical offers was assessed, with particular attention to the quality of the materials and to the verification of the compliance of the presented solutions with the project requirements.

Features:

- Ambient Temperature: 1°C ÷ 55°C;

- Operating temperature: 500°C;

- Humidity: 100%;

- Air: arid, saline and contaminated by sand;

- Wind speed: 115km/h.