Project Description

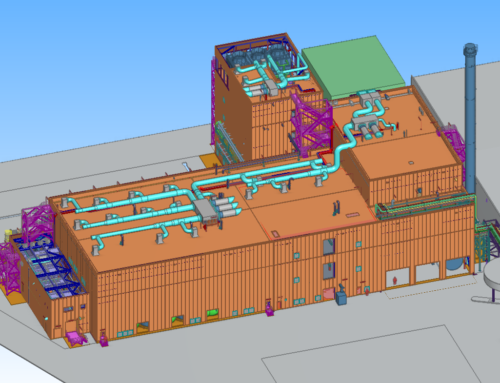

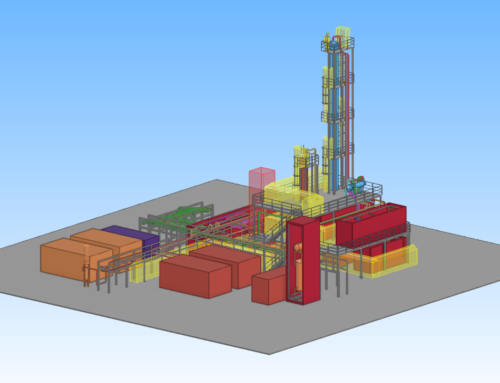

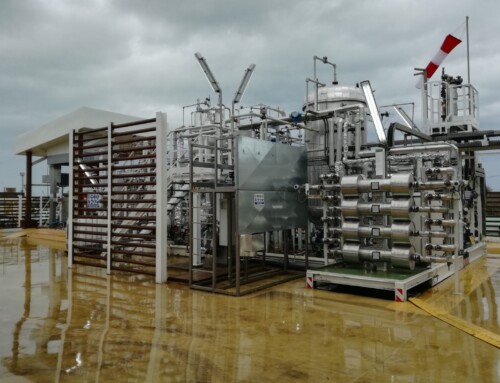

REVAMPING BIODIESEL PLANT

OBJECTIVES

The objectives of this project were the revamping and optimisation of certain systems within the biodiesel production plant through the implementation of multidisciplinary engineering activities (mechanical, electrical and instrumentation). The starting point was a preliminary analysis conducted by Trillini Engineering experts in collaboration with the plant’s technical management, who identified the necessary interventions, the state of the infrastructure and established the technical guidelines for the actions to be taken. This was followed by the multidisciplinary design phase and the drafting of documents and drawings for the final client. The project was then contracted and implemented in several phases during the plant’s periodic shutdowns..

Sector: Clean Energies

Anno: 2020 – 2021

Place: Italy

Direct client: Reserved

Final client: Reserved

MAIN ACTIVITIES

- Mechanical engineering for the revamping of the chilled water generation and distribution system and the evaporative tower system, with the associated pumping system;

- Electrical engineering for the revamping of switchboards and outlets corresponding to the new mechanical systems to be installed; analysis for the revamping of some switchboards and the optimisation and standardisation of the electrical architecture, with new layouts and positioning of the related

rooms; the definition and replacement of electrical equipment in poor condition; - Instrumental engineering associated with the revamping of the new mechanical systems to be installed, with analysis for the merging and replacement of the single supervisory system, the migration of obsolete PLCs, and analysis related to alarm management.

SOLUTIONS

Trillini Engineering’s team of three senior specialists (mechanical, electrical and instrumentation) carried out the project from the initial plant analysis phase to the delivery of the final drawings. The main challenge of this project was to develop a construction detail within an ageing plant, with a lack of existing documentation and with an extremely tight timeframe imposed by the client’s needs, production constraints and plant downtime.