Trillini Engineering is in charge of developing a CFD (Computational Fluido Dynamics) simulation in the framework of a contract for the development of HVAC engineering for two Local Equipment Rooms.

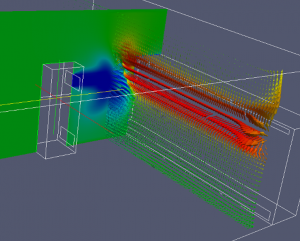

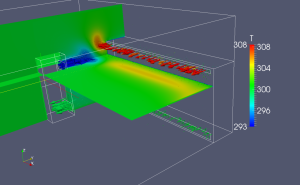

The purpose of the simulation is to identify eventual hot spots in the room thus allowing an optimization of the HVAC system during the design phase instead of during the commissioning phase.

Trillini Engineering has developed a valuable experience in CFD simulations applied to HVAC design support and validation.

Thanks to a twenty-year experience in the design of HVAC system and to the availability in its staff of a PhD Mechanical Engineer expert of models and simulations, Trillini Engineering is capable of developing CFD simulations of complex systems.

A CFD simulation can help in:

- Preventing hot spots

- Identifying the best layout for nozzles and grilles

- Setting the best air speed

- Verifying the impact of a change in the equipment layout or heat losses