Project: Al Zour Refinery Project

Location: Kuwait

Date: 2017 – 2017

Customer: Valvitalia

End customer: KIPIC

Industry: Oil&Gas

Project Details:

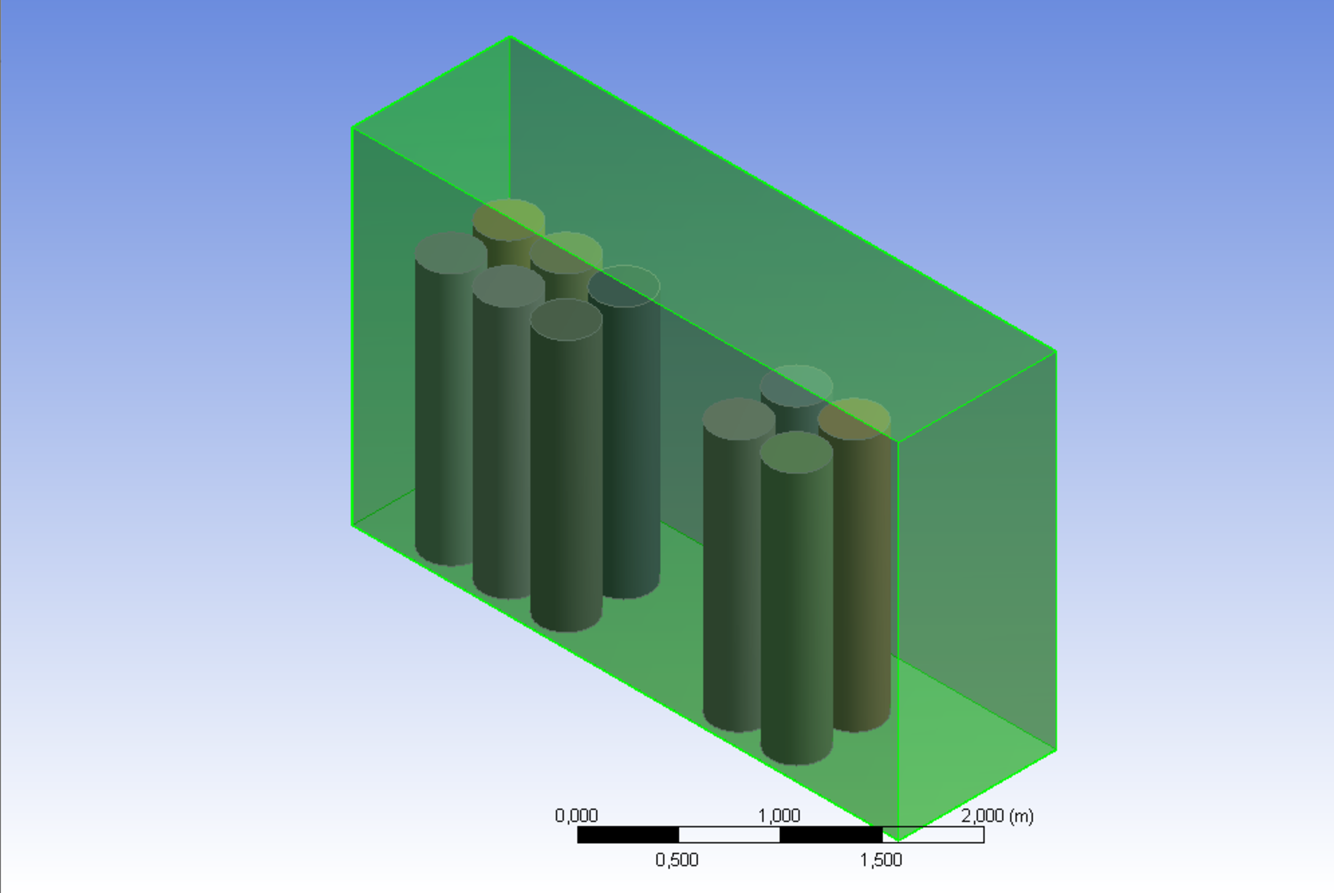

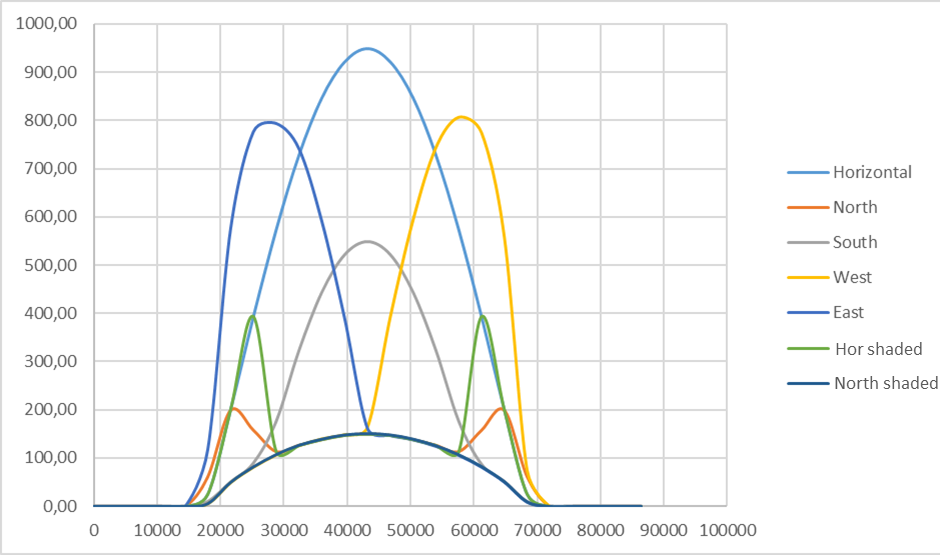

Al Zour Refinery Project Electrical Substation are equipped with firefighting systems (IG541) host in dedicated containers. The scope of work consists in the verification of the internal average temperature under the worst conditions for three different gas cylinder container typologies. High external temperatures (55°C max, 13,3°C daily range) and high solar radiation (950 W max) require the evaluation of internal temperature control strategies. Since containers are installed in classified areas the adoption of active cooling strategies has a relevant impact cost.

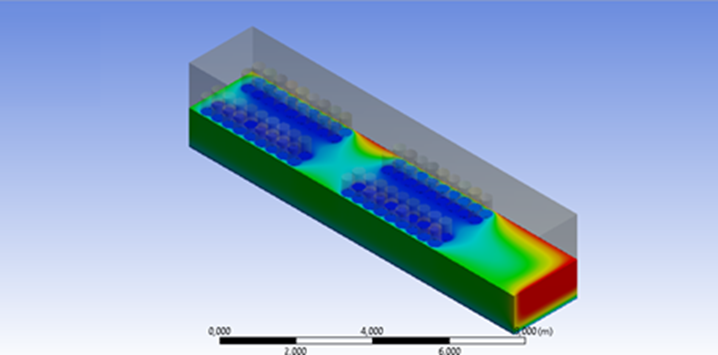

Trillini Engineering was responsible for the development of thermodynamic simulations in order to predict in the worst environmental conditions the average internal temperature inside the containers.

Simulations results shows that in most cases the use of extraction fans and active cooling systems is not required since the use of sunshade and the high heat capacity of gas bottles are enough to maintain internal temperatures under the threshold.

A limited number of containers has to be equipped with extraction fan. This was due to the particular orientation of the containers and to the low number of gas cylinders resulting in a reduced heat capacity.

The simulation was completed using ANSYS software and consisted in the following steps:

- Geometry definition

- Boundary condition definition

- Mesh design

- Calculation

- Report preparation