Trillini Engineering has developed a valuable experience in Computational Fluid Dynamics (CFD) simulations applied to HVAC design support and validation.

Thanks to a twenty-year experience in the design of HVAC system and to the availability in its staff of a PhD Mechanical Engineer expert of models and simulations, Trillini Engineering is capable of developing CFD simulations of complex systems.

Areas of application

HVAC has a key role in ensuring safety and comfort conditions in Oil&Gas facilities. This is particularly true for those areas hosting business critical equipment such as:

- Local Equipment Rooms

- E-Houses

- Substations

- Data Centres

In these buildings, an increasing power density due to high performance equipment (AC/DC transformers, blade servers) and limited space available introduces new challenges during HVAC system design phase.

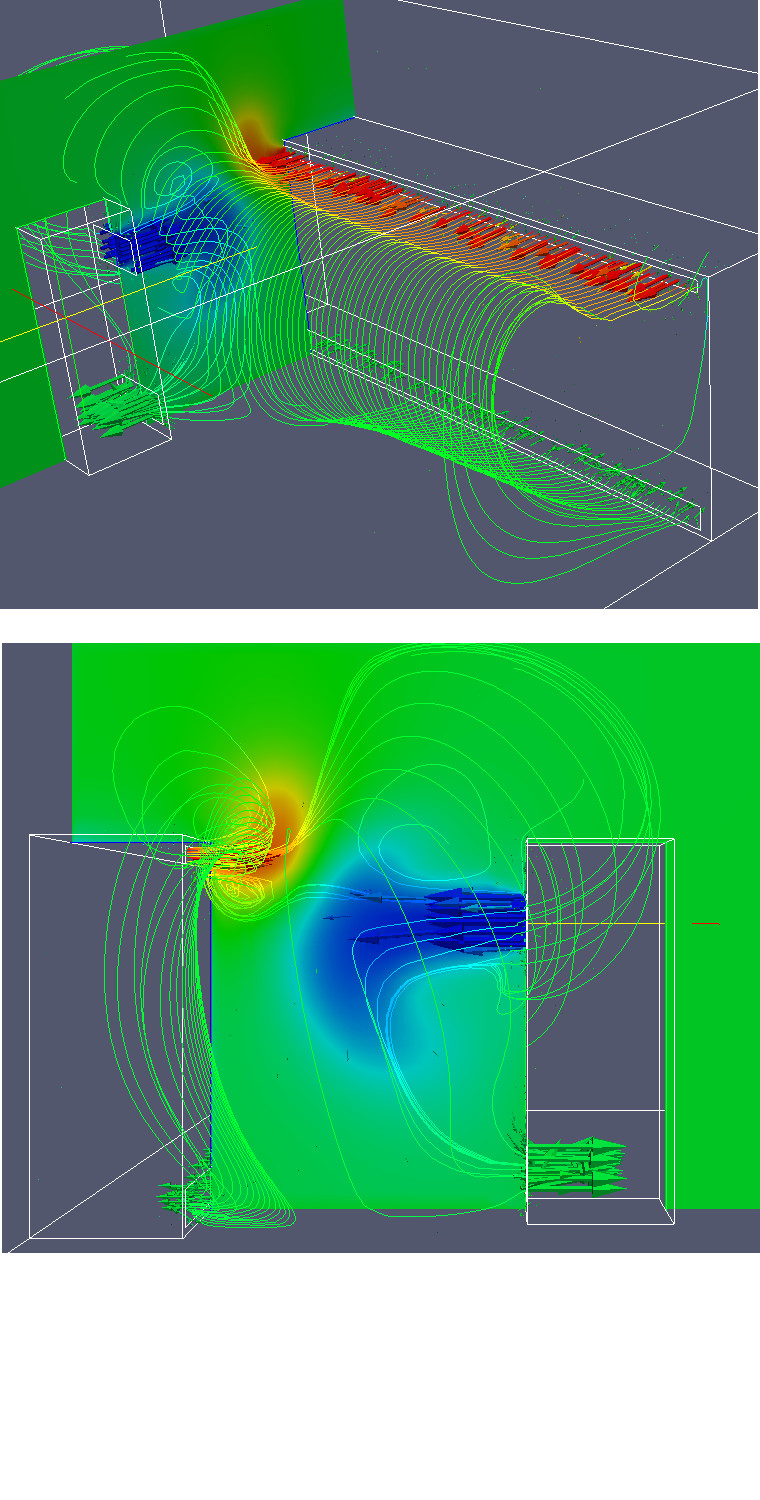

Guaranteeing the correct amount of cooling power and fresh air through the room air conditioning equipment is not enough to ensure the respect of the requirements in terms of equipment and operators comfort conditions.

Services

CFD (Computational Fluid Dynamics) simulations are useful to support the design team during:

- Preliminary design phase

- Design phase

- Commissioning and Setup phase

A CFD simulation can help in

- Preventing hot spots

- Identifying the best layout for nozzles and grilles

- Setting the best air speed

- Verifying the impact of a change in the equipment layout or heat losses

CFD model development includes the following steps:

- Requirements analysis

- Room and volumes drawing

- Meshing

- Test run and grid independency tests

- Mesh adjustments and refinements

- Running in different conditions

- Reporting