Project Description

KASHAGAN FIELD EPC 2, 3 LOCAL EQUIPMENT ROOMS

OBJECTIVES

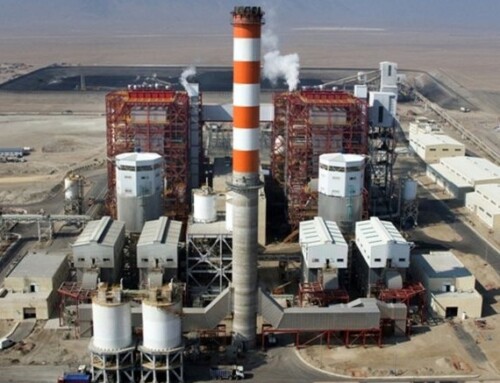

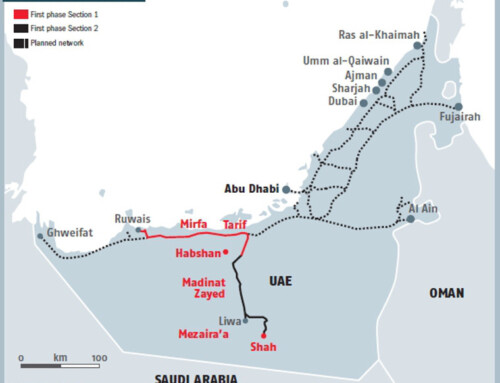

The Kashagan Field is located in the Caspian Sea offshore Kazakhstan, approximately 80 km south of the town of Atyrau. The Experimental Programme (EP) comprises the development of offshore islands (islands A and Dincluding satellite wellhead clusters EPC2, EPC3) in the northern part of the Kashagan East Reservoir.

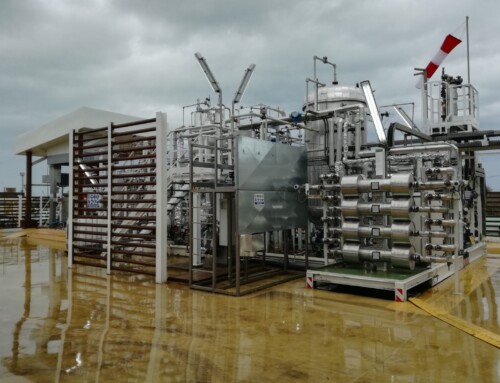

Renco Spa was awarded a contract for the design, material supply, fabrication, inspection, testing, pre-commissioning of two Local Equipment Rooms to be integrated on a Minimum Facilities Wellhead Platform associated with EPC2 and EPC3.

Sector: Oil&Gas

Year: 2015 – 2016

Location: Kashagan, Kazakhstan

Direct client: Renco Spa

Final client: Saipem/ERSAI/NCOC N.V.

MAIN ACTIVITIES

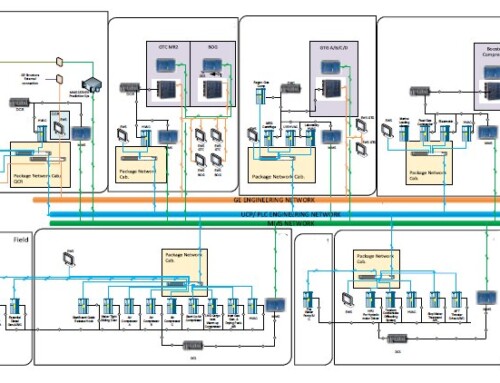

Trillini Engineering was in charge of Project Management and of Project Engineering Management for all the disciplines involved in the project such as Structural, Architectural, HVAC, E&I, F&G.

SOLUTIONS

Trillini Engineering was also responsible for the design of the following systems:

- Architectural Design;

- Structural Design;

- Design of the HVAC system and its Control;

- Emergency Pressurization System (EPS) Design;

- Gas Extinguishing System (GES) Design.

Architectural Design

– Internal layout and false floor design, HVAC/E&I/Piping penetration and installation details, external gutter/downspout and handrail detail, Fire doors and internal lining detail design. All the relative detail drawing, Installation details were part of the Engineering scope.

Structural Design

– Secondary steel structures, external corrugated wall, External container and stack structure design, support for Electrical panels/HVAC/E&I Equipment. All the relative structural shop drawing, details and welding map were part of the Engineering scope.

Design of the HVAC system

– Design of the HVAC system, ranging from the preliminary study to the detailed design of the components, for the design of the HVAC control board layout, of the electro-instrumental system serving the HVAC and the interfaces with central ICSS.

Emergency Pressurization System design

– Design of the system including hydraulic calculation, detailed design, isometric drawing and control philosophy. Gas tanks are located in a rooftop container.

Gas Extinguishing System

– Design of the Inergen system to be installed rooftop including isometric drawing and control philosophy.

Trillini Engineering also took care of the suppliers follow-up throughout the whole design process.

Features:

- Offshore;

- External continuative operating condition: -36 °C to 45 °C – RH 100%;

- A60 Fire rating wall/doors – J15 wall;

- Low temperature steel structures (S355-J2 for primary/secondary structures);

- ATEX atmosphere (zone 2 IIB T3 / zone 1 IIC T3);

- LER internal pressurization obtained by HVAC system;

- Emergency pressurization system;

- INERGEN Gas Extinguishing system;

- SIL Assessment for F&G system/equipment control loop.